KBS Tour FLT Iron Shafts

By Russ Ryden

Russ is the owner of Fit2Score, Dallas Fort Worth, Texas

A Golf Digest America’s 100 Best Clubfitter

![FLTHeroLeft]() Kim Braly has been designing and making shafts for around 40 years. That’s a long time. In my opinion fitting is an experience based art form and is likely to remain so. That said, over 40 years one accumulates an impressive amount of experience.

Kim Braly has been designing and making shafts for around 40 years. That’s a long time. In my opinion fitting is an experience based art form and is likely to remain so. That said, over 40 years one accumulates an impressive amount of experience.

The KBS Tour was the first shaft produced by Femco steel as the KBS brand. We have seen a lot of designs since its introduction, most of which are reviewed here. This year, KBS is introducing its first flighted design. My experience with ‘flighted’ shafts goes back to the Project X Flighted designs. That design was promoted as having the propensity to create the same ball flight height throughout the set. The short irons height apex being lower and the long iron height apex being higher than the conventional set of Project X shafts.

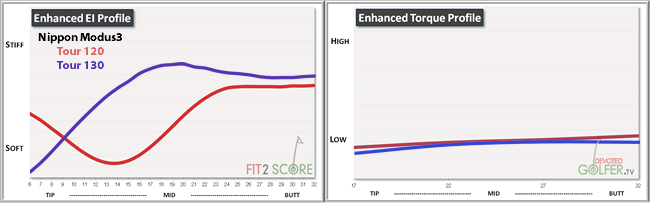

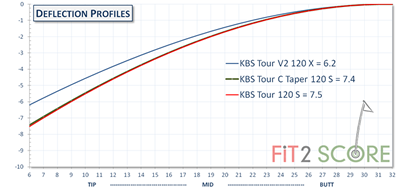

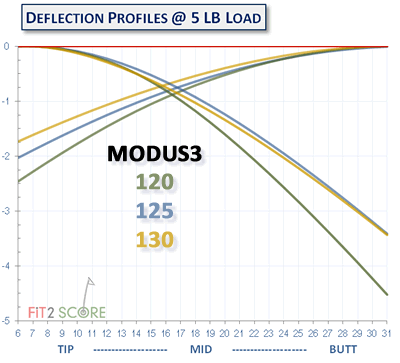

It was not until I measured the KBS Tour FLT shafts and compared them to the KBS Tour that I understood exactly how that is accomplished. In a shaft product line like KBS, the shaft bend profiles are the same for all shafts in the design family. As they get heavier, they get stiffer. And, as they get stiffer for any particular golfer, the launch angle tends to come down. This is what I love about the KBS mix of shafts. They are available in 5 gram increments, with flex designations of R, R+, S, S+ and X. If I want to change a clients launch angle I move the stiffness up or down 5 grams. Now before the professional fitters reading this jump on me, that can also be accomplished by hard stepping or soft stepping the set. Leaving the weight the same but altering the tip lengths.![Tour120S FLTvsSTD]()

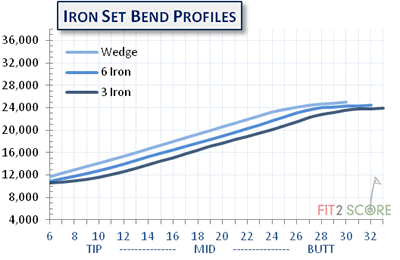

The fundamental concept is that stiffness changes launch angle. When we look at the standard set of KBS Tour shafts we see a difference in stiffness between the 3 iron shaft and the wedge shaft. When we look at the FLT set we see that difference is expanded. The 3 iron shaft is softer, the wedge shaft is stiffer.

How did that standard range of stiffness get established in the first place. In many of the interviews I have done with Kim Braly you hear him say the early work he did on tour with his dad, Dr. Joe Braly was research. They wrote the standard. Using a frequency instrument they evaluated the stiffness of the clubs used by tour players and developed a sense of what the range of stiffness difference was between clubs preferred by the best players of the time. The result of that research was the concept of frequency matched iron sets.

I am certain many of the golfers and club fitter / builders reading this have heard of frequency matching. In its day it was a practical tool for matching iron shaft stiffness when no other tools existed. It is still practiced by some club builders to this day. And there is a long history of misapplication of the concept. That misapplication occurs when shaft tips are dis-proportionally trimmed to hit butt frequency targets. In today’s world of golf shaft production control, constant weight taper sets inherently provide consistent club to club stiffness gradients.

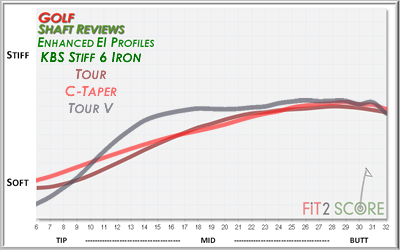

To understand the stiffness gradient of any particular set of irons you must look at the stiffness of the shafts at the ends of the set. This assumes that the shafts within the set have consistent EI profiles. If they do not, no amount of frequency matching is going to fix that problem. It is likely to make it worse. Now with that bit of history behind us, lets look at the illustration above, showing the KBS Tour and the KBS Tour FLT 3 iron and wedge shafts. You will see the stiffness gradient is different. For the frequency practitioners reading this it means the slope, that 8.6 CPM per inch you work to changes.

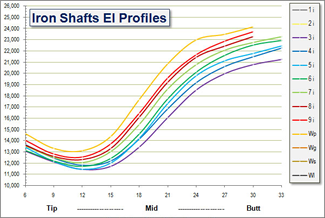

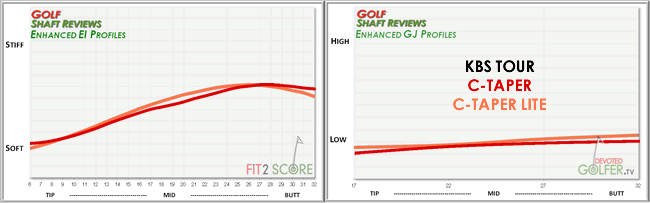

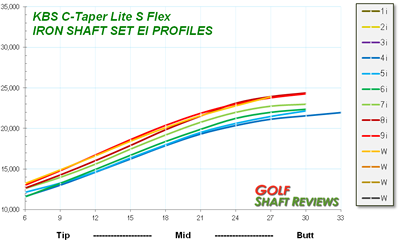

![KBSCTLSet]() Looking at these two designs is a lesson in finding the appropriate set of iron shafts for your swing. Do you want to bring your wedge flight down and your long iron flight up. If so, look for a set of shafts with a steeper stiffness gradient. If not, look into sets with smaller stiffness gradients. Compare this set profile shaft from the KBS CTaper Lite 110S to the charts above. You will see flatter profiles indicating a lower launch propensity design with a conventional stiffness gradient.

Looking at these two designs is a lesson in finding the appropriate set of iron shafts for your swing. Do you want to bring your wedge flight down and your long iron flight up. If so, look for a set of shafts with a steeper stiffness gradient. If not, look into sets with smaller stiffness gradients. Compare this set profile shaft from the KBS CTaper Lite 110S to the charts above. You will see flatter profiles indicating a lower launch propensity design with a conventional stiffness gradient.

In this video Kim and I discuss set stiffness gradients. After a discussion of the KBS Tour 560 and 580 shafts we talk about the FLT design. He tells us this shaft is already getting tour play. When you push the flight apex of those longer irons out, not only is there likely to be some distance gain, but the ball will have a steeper angle of descent. What I refer to as drop and stop trajectory.

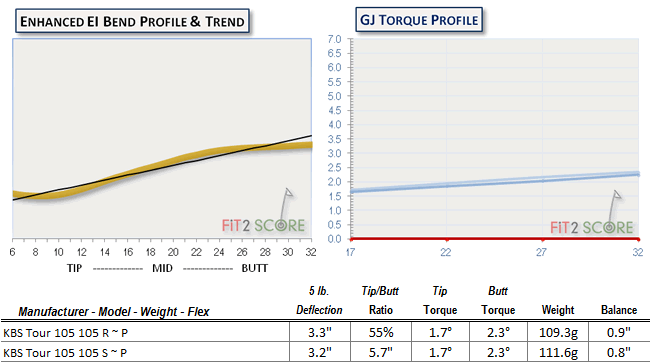

Lets take a look at the numbers in a way I have not presented the here before. This style of information is now incorporated into the latest version of the Fit2Score shaft knowledge base. The set charts shown above are also from that software. ![TourFLTEiTb]()

Radial consistency and shaft to shaft bend consistency within the sets I checked were excellent. Radial consistency was 99,7% with a 0.2% standard deviation hard to soft side. Perfect! Don’t bother aligning these, they are round out of the bag. The tip to butt rations indicate a mid launch as is typical on the KBS Tour. Torque is typical for steel, low. Balance is conventional, the weight range works for the average to tour level player. The low ninety driver swing speed player is going to fit into the 110 or 115 gram R or R+ models.

Because this is such a unique set of iron shafts, this review is going to contain more information than I usually present. Lets start with a look at the weights of the uncut shafts in the sets. As you can see, they clearly get heavier as they get shorter. More so than any ascending weight set I have seen to date. That being the case I did full documentation on a set or irons built with the Tour Issue X100s.

Because this is such a unique set of iron shafts, this review is going to contain more information than I usually present. Lets start with a look at the weights of the uncut shafts in the sets. As you can see, they clearly get heavier as they get shorter. More so than any ascending weight set I have seen to date. That being the case I did full documentation on a set or irons built with the Tour Issue X100s.

True Temper introduced the term “Loading Zone” with the

True Temper introduced the term “Loading Zone” with the  The radial quality of the Project X LZ shafts I tested were all greater than 99%. That is a big number. Spining, aligning or puring these shafts is a waste of time and expense. Label up or label down is the only installation choice that you need to make. They are neutral balanced. I showed the hoop stiffness to illustrate its cofluence with the stiffness profile of steel shafts. To the degree that hoop stiffness adds ‘kick’ to a shaft, the Project X LZ shaft far exceeds any carbon fiber shaft I have seen. And it does so with a very similiar stiffness profile to some carbon fiber shaft designs.

The radial quality of the Project X LZ shafts I tested were all greater than 99%. That is a big number. Spining, aligning or puring these shafts is a waste of time and expense. Label up or label down is the only installation choice that you need to make. They are neutral balanced. I showed the hoop stiffness to illustrate its cofluence with the stiffness profile of steel shafts. To the degree that hoop stiffness adds ‘kick’ to a shaft, the Project X LZ shaft far exceeds any carbon fiber shaft I have seen. And it does so with a very similiar stiffness profile to some carbon fiber shaft designs. The Project X LZ comes in 4 different weights, with weight comes stiffness. The True Temper Project X iron shafts retain their EI profiles as they get stiffer. The same is true for the True Temper Project X shafts. This is much different from the

The Project X LZ comes in 4 different weights, with weight comes stiffness. The True Temper Project X iron shafts retain their EI profiles as they get stiffer. The same is true for the True Temper Project X shafts. This is much different from the  This illustration is a composite taken from the Fit2Score iron set certification process. Each shaft is checked in 2″ increments for stiffness. What you see is a set that is consistent with a slightly stiffer tip in the 9i and wedge. The deflection profiles and EI area show a consistent increase in overall stiffness through out the set. The weights and balance points are indeed constant. Radial integrity is as stated earlier, as close to perfect as I have seen. This set of shafts will build out to as perfect a set of irons as can be made.

This illustration is a composite taken from the Fit2Score iron set certification process. Each shaft is checked in 2″ increments for stiffness. What you see is a set that is consistent with a slightly stiffer tip in the 9i and wedge. The deflection profiles and EI area show a consistent increase in overall stiffness through out the set. The weights and balance points are indeed constant. Radial integrity is as stated earlier, as close to perfect as I have seen. This set of shafts will build out to as perfect a set of irons as can be made.

In the review of the

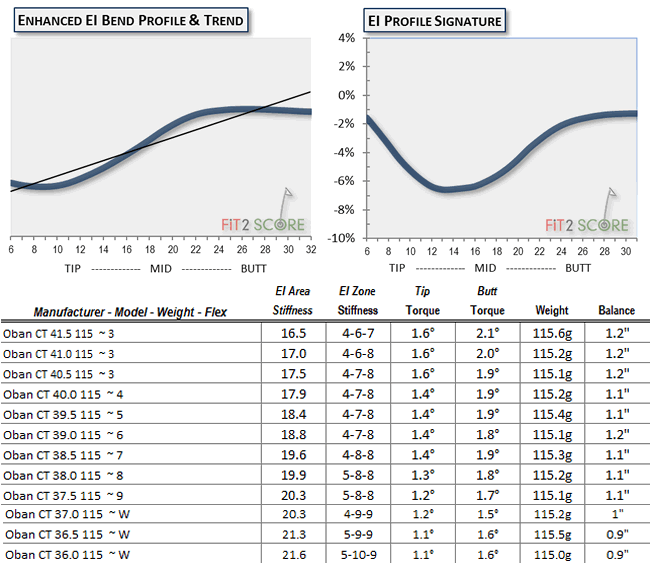

In the review of the  The Oban CT is offered in only one weight, 115 grams. If you are going to have only one weight, this is a good choice. It will fit the majority of amateur golfers. Comparing this profile to other know iron shaft designs I would expect to see a high launch, once again, making it a great fit for the average golfer.

The Oban CT is offered in only one weight, 115 grams. If you are going to have only one weight, this is a good choice. It will fit the majority of amateur golfers. Comparing this profile to other know iron shaft designs I would expect to see a high launch, once again, making it a great fit for the average golfer. Given the similarity to parallel shaft profiles I expected to see a low set stiffness range. That was not the case, While the numbers were smaller as the sets were stiffer, all ranged in what can be called the high mid values for set stiffness range. I don’t really want to use a branded name here, but this a a property introduced by Royal Precision called Flighted. When you see a Set Stiffness Range of 10% or higher the short irons will launch low and the long irons will launch high. For most amateur golfers, this is a good thing.

Given the similarity to parallel shaft profiles I expected to see a low set stiffness range. That was not the case, While the numbers were smaller as the sets were stiffer, all ranged in what can be called the high mid values for set stiffness range. I don’t really want to use a branded name here, but this a a property introduced by Royal Precision called Flighted. When you see a Set Stiffness Range of 10% or higher the short irons will launch low and the long irons will launch high. For most amateur golfers, this is a good thing.